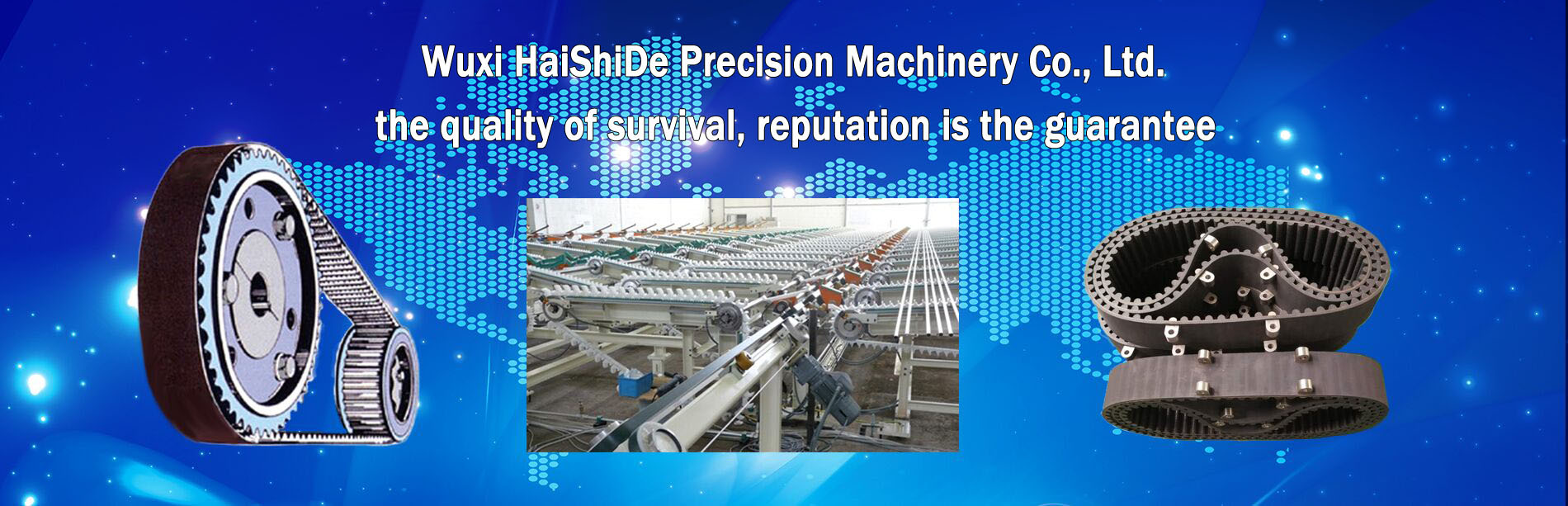

Synchronous belt wheel installed on the correct method of synchronous belt and the synchronizing wheel

Synchronous belt wheel installed on the correct method of synchronous belt and the synchronizing wheel

The correct installation of synchronous belt (1) turn off power, remove the protective cover, unscrew the motormounting bolt. Mobile motor synchronizing with enough slack, do not need to pry open the can remove thesynchronous belt, synchronous belt don't come. (2) remove the old belt, check whether there are abnormal wear.Excessive wear can mean the problems of gear design and maintenance. (3) timing belt replacement selection.(4) clean synchronous belt and synchronous belt wheel, the liquid wiping cloth stained with a little less volatile,soaked in cleaning agent or detergent scrub synchronous belt is undesirable. To remove the oil and dirt, sand orsharp objects scratching, obviously is not desirable. Synchronous belt must be installed before use to keep dry. (5)check if there is abnormal synchronous belt wheel wear or crack, if excessive wear, you must replace the belt wheel. (6) check the belt wheel is a linear symmetric. Synchronous belt wheel linear symmetrical to thetransmission belt especially synchronous belt transmission device operation is very important. (7) check thetransmission parts such as the rest of the symmetry of the bearing and the bearing sleeve, durability andlubrication condition. (8) installed in the synchronous belt wheel synchronous belt is new, not to pry or violently. (9)tightening gear center distance, until the tension measuring instrument measured synchronous belt tension duedate. Hand turn coil driving wheel and tension test. (10) device of bolt tightening torque motor, correct. Since any change in center distance transmission device in operation will lead to bad performance of synchronous belt, itmust ensure that all transmission parts have been tightening. (11) starting device and observe the performance of synchronous belt, to see whether there is abnormal vibration, listen to whether there are abnormal noise, it is best to turn off the machine to check the motor bearing and the situation; if it feels too hot, may be synchronous belt is too tight, or bearing lubrication is asymmetric, or incorrect.